In the domains of ecommerce, retail, and manufacturing, the notion of “backorder” frequently comes into play. This concept often introduces a complex mix of challenges and opportunities.

Understanding the nuances of backorders is about managing stock shortagesand leveraging these situations to enhance customer relationships and optimize supply chain strategies. Dive into our comprehensive article to develop a deep understanding of backorders and acquire the skills to navigate them effectively

Definition of backorder

A backorder is a situation in which a customer places an order for an item that is not currently in stock or available for immediate shipment but is expected to be replenished and shipped at a later date. This typically occurs when the demand for a product exceeds its current supply.

In a backorder scenario, the seller still accepts the order and commits to delivering the product once it becomes available, rather than canceling the order or refusing to accept it. This practice is common in ecommerce, retail and manufacturing industries and is a key aspect of inventory management.

What is a partial backorder?

A partial backorder occurs when a customer places an order for multiple items, but only some of those items are currently out of stock and cannot be immediately fulfilled. In this scenario, the available items are shipped to the customer, while the unavailable items are placed on backorder and shipped later when they become available.

For example, imagine a customer ordering three different products from a store. Two of the products are in stock, and one is not. The store would ship the two available products immediately and send the third product once it’s back in stock, hence creating a partial backorder for that item.

Partial backorders are a common occurrence in ecommerce, retail and supply chain management, and they require careful handling to ensure customer satisfaction. Effective communication about the status of the backordered items and expected shipping times is crucial in these situations. This approach allows businesses to fulfill at least part of the order promptly, which can help maintain a positive customer relationship even when a full order cannot be immediately completed.

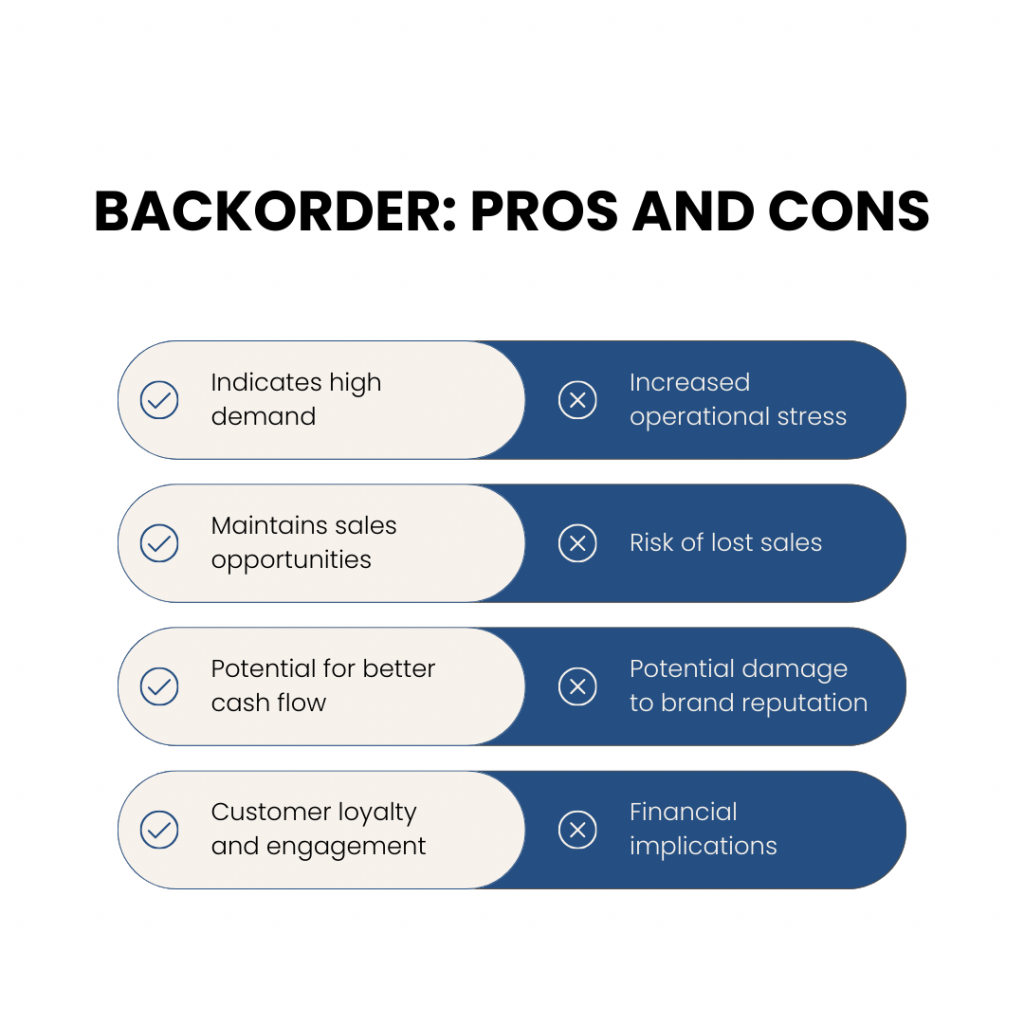

Is backorder good or bad?

Backorders are a double-edged sword. They can benefit businesses by indicating demand and maintaining sales, but they also require careful management to avoid customer dissatisfaction. The classification of backorders as either good or bad depends on the context and perspective.

We’ll consider the business viewpoint.

Pros of backorders

A. Indicates high demand

Backorders reflect strong consumer interest in a business product, which is a positive sign for a business’s market appeal and potential growth. It helps in identifying which products are most valued by customers, guiding future business product development and marketing strategies.

B. Maintains sales opportunities

By accepting backorders, business can secure sales that might otherwise go to competitors or be lost altogether if customers are turned away due to a lack of immediate stock. This approach helps businesses retain customers willing to wait for the products, ensuring long-term revenue.

C. Potential for better cash flow

If customers pay upfront for backordered items, it can provide the business with immediate working capital. This cash flow can be particularly beneficial for a business itself or for funding production costs.

D. Customer loyalty and engagement

Customers who are willing to place backorders demonstrate a high level of commitment and trust in the business or product. This can be leveraged to build stronger customer relationships and loyalty.

Cons of backorders

A. Increased operational stress

Managing backorders adds complexity to inventory and order management, requiring additional tracking, communication, and logistical arrangements. It can strain business resources, especially in small businesses with limited staff or in companies with less sophisticated inventory systems.

B. Risk of lost sales

If the wait for a backordered item is too long, customers might cancel their orders and purchase similar products from a business’ competitors. There is a risk of losing the immediate sale and future business from dissatisfied customers.

C. Potential damage to brand reputation

Frequent or extended backorders, especially if not communicated effectively, can harm the business reputation for reliability and customer service. This can affect customer perceptions and deter potential new customers.

D. Financial implications

There may be financial risks, such as issuing refunds for delayed backorders or incurring additional costs in expediting production or shipping to fulfill backorders. Holding costs for increased safety stock to prevent future backorders can also impact business financials.

How backorders work

Let’s go through a step-by-step explanation of how backorders typically work.

1. Customer places an order

A customer selects a product and completes the purchase process through a company’s sales channel. This can be an ecommerce store, a physical retail outlet, or any other point of sale. The order is logged into the company’s order management system.

2. Product is out of stock

Upon processing the order, the company discovers that the product is not available in their inventory. This situation may arise due to various reasons, such as higher-than-anticipated demand, supply chain disruptions, or production delays.

3. Order is accepted as a backorder

The company decides to accept the order and fulfill it once the product is back in stock instead of canceling it or suggesting an alternative item. This decision is typically based on the estimated time it would take to restock and the company’s policy on backorders.

4. Communication with the customer

The company proactively contacts the customer, typically via email or phone, to inform them that the ordered item is on backorder. This communication includes an estimated restock date and the expected time frame for delivery.

5. Fulfillment of partial orders (if applicable)

In cases where the order includes multiple items and only some are on backorder, the company ships the available items immediately. The company informs the customer about the partial shipment and provides details about the backordered item(s), including expected shipping dates.

6. Managing the backorder

Internally, the company coordinates with suppliers, manufacturers, or their production department to expedite the restocking of the backordered item. This might involve placing urgent orders with suppliers, reallocating inventory from other locations, or ramping up production.

7. Shipping the backordered item

As soon as the product is back in stock, the company prioritizes the preparation and shipment of backordered items. The fulfillment process includes quality checks, packaging, and product dispatching through the chosen logistics service. The company then updates the customer with the shipment details, including a tracking number and expected delivery date.

8. Customer receives the product

The customer receives the backordered item. Ideally, the product arrives within the estimated delivery window, meeting or exceeding the customer’s expectations.

After the customer has received the product, the company might reach out for feedback. This can be through a customer satisfaction survey, a follow-up call, or an email. This step is crucial for assessing the impact of backorders on customer satisfaction and identifying areas for improvement.

How long does a backorder take?

The duration of a backorder can vary widely depending on several factors, and there is no standard time frame that applies universally. The length of time a customer might wait for a backordered item is influenced by the following:

- Nature of the product. Some products, especially custom-made or specialty items, may take longer to restock than mass-produced items.

- Supply chain complexity. The complexity of the supply chain plays a significant role. If a product needs to be sourced internationally or involves intricate manufacturing processes, it can prolong the backorder duration.

- Reason for backorder. The specific reason for the backorder impacts the wait time. For instance, if the delay is due to a temporary disruption in the supply chain, the backorder might be resolved relatively quickly. However, if the issue is due to a shortage of raw materials or a significant increase in demand, it could take much longer to resolve.

- Logistics and shipping. Once the product is available, shipping logistics also play a part. Faster shipping methods can reduce the overall wait time for the customer.

Typical time frames

- Short-term backorders. These might last a few days to a week, often due to minor inventory miscalculations or short-term supply chain disruptions.

- Medium-term backorders. These can last from a few weeks to a month, possibly due to larger supply chain issues or delays in manufacturing.

- Long-term backorders. In some cases, backorders can extend beyond a month, especially for highly specialized products or during extensive supply chain crises.

Example of a backorder: Launch of a new smartphone

Let’s consider a real-world example to illustrate a backorder scenario.

Situation:

A popular tech company, “TechNova,” announces the release of their latest smartphone model, the “TechNova X1.” Due to the brand’s popularity and the highly anticipated features of the new model, pre-order demand is exceptionally high.

1. Pre-order phase.

TechNova opens pre-orders for the TechNova X1, and within days, the demand surpasses the initial stock available. The company continues to accept orders, informing customers that new orders are now on backorder due to the high demand.

2. Backorder notification.

Customers who placed orders after the initial stock was depleted receive notifications from TechNova. The notification explains that their order is on backorder and provides an estimated shipment date, which is a month away, due to the time required for additional production and shipping.

3. Managing the backorder.

Behind the scenes, TechNova works closely with its manufacturing partners to expedite production of the TechNova X1. The company updates its inventory system and keeps track of the backordered units.

4. Fulfilling the backorder.

Within the next month, TechNova will successfully increase production and begin shipping the backordered smartphones. Customers are notified via email when their TechNova X1 is shipped, with tracking information provided.

5. Customer receipt and follow-up.

Customers receive their TechNova X1 smartphones, albeit later than those who pre-ordered before the stock ran out. TechNova follows up with a satisfaction survey and offers support for any issues related to the new device.

Key points of this example

- High demand product. The TechNova X1’s popularity leads to rapid sell-out and subsequent backorders.

- Transparent communication. TechNova keeps customers informed about the backorder status and provides estimated delivery dates.

- Efficient resolution. The company works diligently to fulfill backordered items as quickly as possible.

- Customer satisfaction. Despite the delay, customers are generally satisfied as they were kept informed and eventually received the highly anticipated product.

This example demonstrates how backorders can occur with high-demand products, especially during new releases, and highlights the importance of effective communication and efficient supply chain management in handling backorders.

What causes backorders?

Backorders can be caused by a variety of factors, often related to discrepancies between supply and demand or disruptions in the supply chain. Here are some of the common causes.

Reason #1: Unexpected demand surges

This occurs when a product’s popularity exceeds predictions. For example, a viral social media post can lead to a sudden spike in demand for a specific item. Businesses struggle to replenish stock quickly enough to meet this unexpected increase in sales.

Reason #2: Manufacturing delays

Manufacturing issues such as equipment failure, labor shortages, or delays in receiving raw materials can slow down production. This is often seen in industries like electronics, where complex manufacturing processes are involved.

Reason #3: Inventory management errors

Inaccurate demand forecasting can lead to insufficient stock levels. If a business underestimates the popularity of a product or fails to account for seasonal demand variations, it may run out of stock faster than anticipated.

Reason #4: Just-in-Time (JIT) inventory practices

JIT systems aim to reduce inventory holding costs by ordering stock just in time for production or sales. However, any disruption in the supply chain can lead to immediate backorders, as there is little to no buffer stock available.

Reason #5: Seasonal fluctuations

Certain products are in high demand during specific seasons, like air conditioners in summer or heaters in winter. Failure to adequately prepare for these predictable demand increases can result in backorders.

Reason #6: Vendor reliability issues

Dependence on a single supplier or vendors facing their own challenges (like financial instability or production issues) can result in unreliable supply and backorders.

Reason #7: Rapidly changing market trends

In industries like fashion or technology, trends can shift quickly. Businesses that cannot adapt their inventory to these rapid changes risk running out of popular items.

How do you account for backorders?

Accounting for backorders involves several key steps to ensure accurate financial reporting and inventory management. Here’s how businesses typically handle the accounting for backorders:

1. Order recording and tracking

When a customer orders backordered items, the order should be recorded in the company’s order management system. This includes details of both in-stock and backordered items.

Backordered items are tracked separately in the system. This tracking is essential for inventory management and for providing accurate information to customers about their order status.

2. Revenue recognition

Accounting standards (such as GAAP or IFRS) dictate when a company can recognize revenue from sales. In many cases, revenue from a backordered item is not recognized until the item is actually shipped and delivered.

If payment is received for a backordered item before it is shipped, the amount is recorded as deferred revenue (a liability on the balance sheet) until the item is shipped and revenue can be recognized.

3. Inventory accounting

Backordered items are typically not considered part of the available inventory. They are accounted for separately to reflect that they are committed to fulfilling customer orders.

The cost associated with backordered items is not included in COGS until the items are actually shipped.

Learn about the COGM formula and how it differs from COGS.

4. Financial reporting

Unfulfilled backorders where payment has been received will reflect on the balance sheet as deferred revenue. Revenue from backordered items will appear on the income statement in the period when the goods are shipped, not when the order is initially placed.

5. Communication with financial stakeholders

Businesses should maintain transparency about backorders in their financial reporting, especially if the volume of backorders is significant and could impact financial results. It’s important to communicate how backorders are affecting cash flow, as payments received for backordered items can provide a temporary boost to cash reserves.

6. Monitoring and adjustments

Regularly reviewing backorder levels and their impact on financials is crucial. This helps in making informed decisions about inventory management, production planning, and sales forecasting.

If there are significant delays or changes in the status of backordered items, accounting records may need to be adjusted, such as changing the estimated delivery period for deferred revenue recognition.

Best practices

- Integrated systems. Using an integrated system that connects inventory management with accounting software helps in accurately tracking and accounting for backorders.

- Regular audits. Conducting regular audits to ensure that backorders are being accounted for correctly and in compliance with relevant accounting standards.

Proper business accounting for backorders is essential for accurate financial reporting, inventory management, and maintaining compliance with accounting standards.

Tips for minimizing backorders

Tip #1. Accurate demand forecasting

Implement tools for analyzing sales trends, seasonal patterns, and market shifts. Consider external factors like economic conditions or industry trends. Regularly update forecasts based on real-time sales data and market intelligence.

Tip #2. Robust inventory management

Utilize a system that provides a clear view of what’s in stock, what’s ordered, and what’s in transit at all times. Establish clear reorder thresholds for each product to trigger automatic restocking.

Tip #3. Diversify suppliers

Source materials or products from multiple suppliers to avoid reliance on a single entity. This reduces the risk if one supplier faces delays or shortages. Evaluate and onboard backup suppliers, ensuring they meet quality and delivery standards.

Tip #4. Leverage technology

Invest in advanced software that uses AI and machine learning to predict future business inventory needs more accurately. Automate order processing to reduce the time between order receipt and fulfillment.

Tip #5. Safety stock

Determine the right level of safety stock for different products, considering factors like lead time, demand variability, and the criticality of the product. Regularly review and adjust safety stock levels based on changing business conditions.

Tip #6. Regular inventory review

Schedule and conduct business inventory audits to identify discrepancies and address them proactively. Analyze inventory turnover rates to identify slow-moving items that may be taking up valuable space and resources.

Tip #7. Responsive supply chain

Develop a supply chain that can quickly scale up or down based on demand changes. Implement a system for continuous monitoring of supply chain performance.

Tip #8. Plan for contingencies

Develop and regularly test plans for dealing with various types of disruptions, such as supplier failures, logistics issues, or natural disasters. Include strategies for rapid response and communication in the event of a disruption.

Conclusion

Backorders, while challenging, are an integral part of inventory management in modern business. Effectively managing them requires a mix of good communication, technological aid, and strategic planning. As businesses continue to navigate the complexities of supply chains and consumer demands, the ability to manage backorders efficiently will remain a key factor in maintaining a competitive edge.

FAQs about backorders

What exactly is a backorder in retail and ecommerce?

A backorder occurs when a product is not currently in stock but is still ordered by a customer. The business commits to delivering the item once it is restocked rather than canceling the order.

How does a backorder differ from an out-of-stock situation?

An out-of-stock situation means the business product is temporarily unavailable, and the customer cannot place an order. In contrast, a backorder allows customers to order the item with the understanding that it will be shipped later.

Can backorders affect a company’s financial reporting?

Yes, backorders can affect business financial reporting, especially regarding revenue recognition and inventory accounting. Typically, business revenue is recognized when the product is shipped, not when the order is placed.

What is a partial backorder, and how is it handled?

A partial backorder occurs when only some items in an order are out of stock. The business ships the available items first, and the remaining items are shipped later. Effective communication and tracking are essential in these cases.

.png)