The perpetual inventory system represents a significant advancement in this area, providing real-time tracking and management of inventory. By exploring its mechanisms, benefits, and implementation strategies, we uncover how the perpetual inventory system is not just a tool but a game-changer in the world of inventory management.

What is a perpetual inventory system?

A perpetual inventory system is a method of accounting for inventory that records the sale or purchase of inventory immediately through the use of computerized point-of-sale systems and enterprise asset management software. This system continually updates inventory records, providing a highly accurate and real-time view of current stock levels.

Key characteristics of the perpetual inventory system

Continuous updating

In a perpetual inventory system, inventory records are constantly updated after every inventory-related transaction, like sales, purchases, or returns. This results in a real-time reflection of the current stock levels, ensuring that inventory data is always current and accurate.

Learn more about inventory system and why you need one.

Automated data entry

Automation is a core characteristic where the system automatically records inventory transactions. This reduces the manual effort and errors associated with manual data entry, significantly enhancing accuracy and efficiency.

Direct link to Point-of-Sale (POS) systems

Integration with POS systems is key in retail environments. When a sale is made, the system automatically deducts the sold items from the inventory, updating records in real time. This integration ensures accuracy in both sales and inventory records.

Real-time inventory valuation

The system keeps a continuous, up-to-date record of the inventory’s value, reflecting the cost of goods available for sale at any moment. This is crucial for financial reporting and decision-making.

Detailed record-keeping

Perpetual inventory systems maintain detailed records of all inventory transactions, providing a comprehensive history of each item’s movement. This includes dates, quantities, and locations of stock movements, offering invaluable data for tracking and analysis.

Scalability

The system is designed to be scalable, making it suitable for businesses of all sizes. It can handle varying levels of inventory complexity and can be expanded as a business grows.

Access to detailed analytics

These systems often come equipped with analytics tools that provide insights into inventory trends, sales patterns, and performance metrics, assisting in strategic decision-making.

Customization and flexibility

Perpetual inventory systems are typically customizable to meet the specific requirements of a business. They offer flexibility in setting up parameters like reorder points, safety stock levels, and reporting formats, tailoring the system to the unique needs of the business.

When to use a perpetual inventory system

Deciding when to use a perpetual inventory system depends on various factors related to the nature and needs of a business. Here are some scenarios and considerations that indicate when implementing a perpetual inventory system might be beneficial:

- For businesses with frequent transactions (e.g., retail stores, supermarkets).

- For managing a wide variety of products or multiple storage locations.

- For businesses where immediate inventory data impacts operations (e.g., JIT manufacturing).

- For avoiding stockouts in critical sales environments or reducing overstock costs.

- For businesses needing inventory data integration with other systems (accounting, sales, etc.).

- For businesses that rely on timely inventory reports for decision-making.

- For industries with strict inventory tracking and reporting regulations.

- For automating inventory processes and reducing manual labor.

- For growing businesses needing a scalable inventory management solution.

However, a perpetual inventory system may not fit every business best. Small businesses with limited inventory, those without complex inventory management, or businesses with limited budgets for technological investments might find a simpler system, like a periodic inventory system, more suitable and cost-effective.

What are the steps of a perpetual inventory system?

Implementing a perpetual inventory system involves several key steps to ensure its effective operation and integration with a business’s existing processes. Here are the primary steps:

Step 1. Assessment of business needs

Evaluate the current inventory management processes and identify specific needs and goals for implementing a perpetual inventory system. Consider factors like the size of the inventory, the complexity of operations, and integration requirements with other business systems.

Step 2. Selection of appropriate technology and software

Choose the right inventory management software that suits the business’s needs. This software should be capable of handling real-time tracking, reporting, and integration with other systems like accounting and sales.

Decide on the appropriate technology for tracking inventory, such as barcoding or RFID systems, based on the nature and volume of inventory.

Step 3. Infrastructure setup

Install necessary hardware, such as barcode scanners, RFID readers, and computer systems.

Set up a network infrastructure that supports real-time data transfer and access.

Step 4. System configuration and integration

Configure the inventory management software to align with the business’s operational processes.

Integrate the perpetual inventory system with other business systems, such as point-of-sale (POS) systems, ecommerce platforms, and accounting software.

Step 5. Database creation and inventory coding

Create a comprehensive inventory database, including details of each item such as SKU (Stock Keeping Unit) numbers, descriptions, prices, and quantities. Assign barcodes or RFID tags to all inventory items and ensure they are correctly entered into the system.

Step 6. Training and development

Train staff on how to use the new system and technologies. This includes training on scanning items, updating inventory data, and understanding system reports. Develop standard operating procedures for handling inventory transactions within the perpetual inventory system.

Step 7. Ongoing monitoring and maintenance

Regularly review inventory data for accuracy and conduct physical inventory counts periodically to reconcile with system records. Update the system as needed to accommodate changes in inventory, business processes, or technology advancements.

Step 8. Analysis and reporting

Utilize the system’s reporting and analytics tools to gain insights into inventory performance, such as turnover rates, trends, and stock levels. Make informed decisions based on the data analysis to optimize inventory management and improve overall business efficiency.

Continuously assess the effectiveness of the perpetual inventory system and make improvements as necessary. Stay updated with new technologies and practices in inventory management to ensure the system remains efficient and effective.

What are the advantages of a perpetual inventory system?

The perpetual inventory system offers several significant advantages, making it a preferred choice for many businesses:

Real-time inventory tracking

The system provides up-to-date information on inventory levels at any given moment. This real-time tracking helps in quickly identifying which items are in stock, which are running low, and which are out of stock, enabling more responsive inventory management.

Increased accuracy

By automating the tracking of inventory transactions, the perpetual inventory system reduces the likelihood of errors inherent in manual record-keeping. This heightened accuracy is crucial for maintaining reliable inventory records and for ensuring that financial reporting is based on precise data.

Improved decision making

Access to real-time and accurate inventory data allows businesses to make more informed decisions regarding purchasing, sales, and marketing strategies. It helps identify sales trends, customer preferences, and optimal reorder points, which can lead to more effective and profitable business operations.

Enhanced efficiency

Automation of inventory tracking saves time and labor costs associated with manual inventory counts. The system allows for more efficient use of staff time, as employees can focus on other tasks instead of spending time on routine inventory checks.

Better financial management

With perpetual inventory systems, businesses can more accurately track their cost of goods sold (COGS) and inventory levels, which is crucial for precise financial analysis and budgeting. It also aids in more effective cash flow management, as it provides insights into how much capital is tied up in inventory.

Reduced risk of stockouts and overstocking

The system allows businesses to maintain optimal inventory levels, reducing the risk of stockouts (which can lead to lost sales) and overstocking (which ties up capital and increases storage costs).

Seamless integration with other systems

Perpetual inventory systems often integrate smoothly with other business systems, such as point-of-sale (POS) systems, accounting software, and ecommerce platforms. This integration provides a unified view of business operations, enhancing overall operational efficiency.

Facilitates better customer service

By ensuring that inventory levels are accurately maintained, businesses can respond more effectively to customer demands. This can lead to increased customer satisfaction and loyalty, as customers are less likely to face issues like delayed orders due to stockouts.

Valuable insights and analytics

Modern perpetual inventory systems often come with analytics tools that provide valuable insights into inventory trends, sales patterns, and product performance. This data can be used to optimize inventory levels, develop targeted marketing campaigns, and improve overall business strategy.

What are the disadvantages of a perpetual inventory system?

High initial setup costs

Implementing a perpetual inventory system often requires a significant initial investment in technology, such as inventory management software, barcode scanners, RFID systems, and potentially upgraded computer systems.

Complexity and training requirements

The system can be complex to set up and maintain. Employees need comprehensive training to effectively use the new technology and understand the system, which can be time-consuming and costly.

Dependence on technology

A perpetual inventory system is heavily reliant on technology, which means that technical issues, system failures, or data breaches can significantly disrupt operations. Regular maintenance and updates are necessary to keep the system running smoothly.

Over-reliance on system accuracy

While the system is designed to be accurate, there is a risk of becoming overly reliant on its automated processes. Discrepancies can still occur due to reasons like theft, data entry errors, or damaged goods, making occasional physical counts necessary for verification.

Integration challenges

Integrating a new perpetual inventory system with existing systems (like accounting or procurement) can be challenging and may require additional time and resources to ensure seamless operation.

Potential for increased complexity in inventory analysis

The wealth of data and real-time tracking can sometimes make inventory analysis more complex, particularly for businesses not accustomed to handling large volumes of data.

Scalability issues

While the system is scalable, expanding its capabilities to match business growth can require additional investments in software upgrades or additional hardware.

Ongoing maintenance and support costs

Regular software updates, system maintenance, and technical support incur ongoing costs, which can be significant, especially for small to medium-sized businesses.

Risk of data overload

The system generates a large amount of data, which can be overwhelming for businesses that do not have the capability to analyze and utilize this data effectively.

Challenges in adaptation to certain business models

Some business models or industries may find it challenging to adapt the perpetual inventory system to their specific needs, especially if their inventory is not easily tagged or tracked with standard methods.

What’s the difference between a perpetual inventory system and a periodic inventory system?

The perpetual inventory system and the periodic inventory system are two distinct methods used for tracking inventory in businesses, each with its own unique approach and characteristics. Understanding the differences between these two systems is essential for choosing the right inventory management strategy.

Perpetual inventory system

- Continuously updates inventory records in real-time after each sale, purchase, or return. Provides an up-to-date and accurate count of inventory at all times.

- Relies heavily on technology like barcoding, RFID (Radio-Frequency Identification), and inventory management software. Requires electronic data capture systems and integration with point-of-sale (POS) systems.

- Offers continuous updating of financial records, closely aligning inventory records with accounting data. Enables real-time tracking of Cost of Goods Sold (COGS) and other financial metrics.

- Provides more accurate inventory records by minimizing human errors associated with manual counting. Reduces discrepancies between physical inventory and inventory records.

- Generally more expensive to implement due to the technology and systems required. Involves a more complex setup and ongoing maintenance.

- Allows for detailed and frequent reporting on inventory status, enabling better decision-making and planning. Facilitates in-depth analysis of inventory trends and sales patterns.

Periodic inventory Ssystem

- Updates inventory records at specific intervals (e.g., monthly, quarterly, annually) rather than continuously. Involves physically counting inventory at each interval to update records.

- Does not necessarily require sophisticated technology or systems. Inventory tracking is often done manually or with minimal technological assistance.

- Updates to financial records (like COGS) are made only at the end of each interval, not continuously. This may result in a lag between actual inventory levels and recorded financial data.

- More prone to errors and discrepancies due to less frequent updates and reliance on manual counts. This can lead to issues like stockouts or overstocking due to outdated inventory information.

- Generally, it is less expensive to implement and maintain as it requires fewer technological resources. Simpler to set up and operate, especially for small businesses with limited inventory.

- Provides less frequent insights into inventory status, which may be sufficient for businesses with slow-moving inventory. Offers limited capability for detailed analysis and real-time decision-making.

Key differences summarized

| Perpetual inventory system | Periodic inventory system |

| Real-time inventory tracking | Interval-based inventory tracking |

| Technology-dependent | Less technology reliance |

| Financial record integration | Delayed financial record updates |

| Higher accuracy | Lower accuracy |

| More expensive to implement | Lower cost and simplicity |

| Detailed and frequent reporting on inventory status | Less frequent reporting |

Choosing between these systems depends on the specific needs, resources, and scale of the business. High-volume businesses or those requiring precise inventory management often benefit more from a perpetual system, while smaller businesses with limited inventory might find a periodic system more practical and cost-effective.

What are the formulas used in perpetual inventory methods?

In the perpetual inventory system, several key formulas are used to manage and analyze inventory effectively. These formulas help maintain accurate inventory records, calculate financial metrics, and make informed decisions. Here are some of the primary formulas used in the perpetual inventory method:

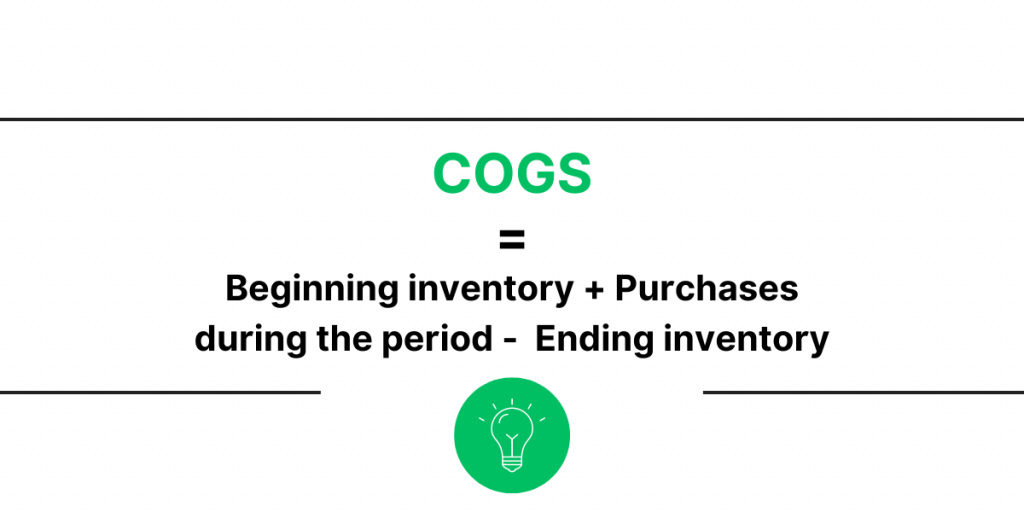

Cost of Goods Sold (COGS)

COGS is a critical financial metric that represents the direct costs attributable to the production of the goods sold by a company. In a perpetual system, COGS is calculated continuously as sales occur.

Formula:

Learn how to account for sales transactions and track COGS with Synder.

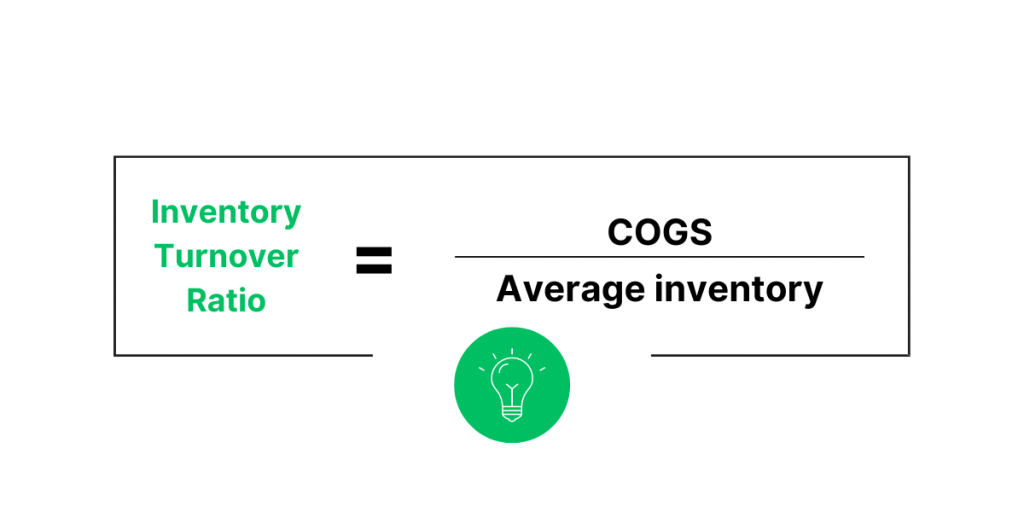

Inventory turnover ratio

This ratio measures how often inventory is sold and replaced over a period. A higher turnover indicates efficient inventory management.

Formula:

Where Average Inventory = (Beginning Inventory + Ending Inventory) / 2

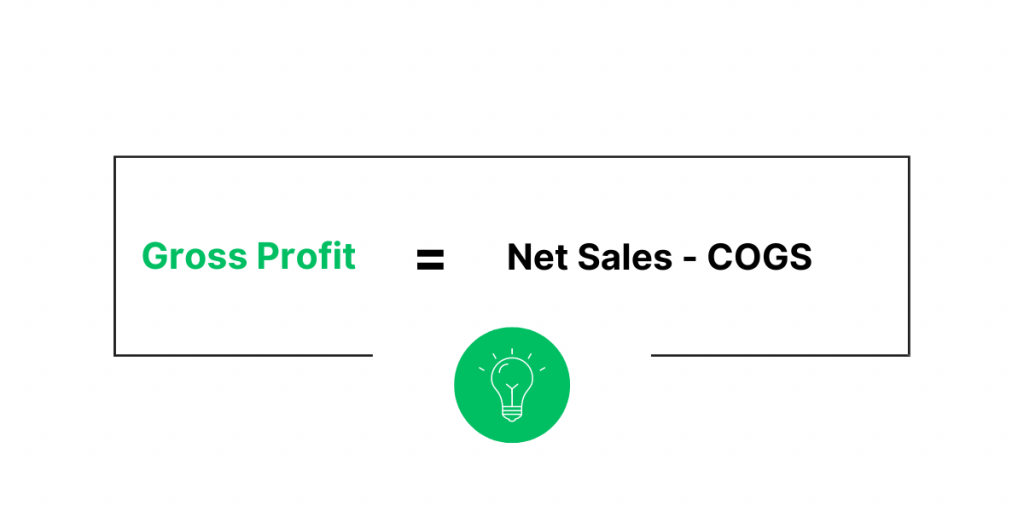

Gross profit

Gross profit is the profit a company makes after deducting the costs associated with making and selling its products (COGS).

Formula:

Net sales

Net sales are the amount of sales generated by a company after deducting returns, allowances for damaged or missing goods, and any discounts allowed.

Formula:

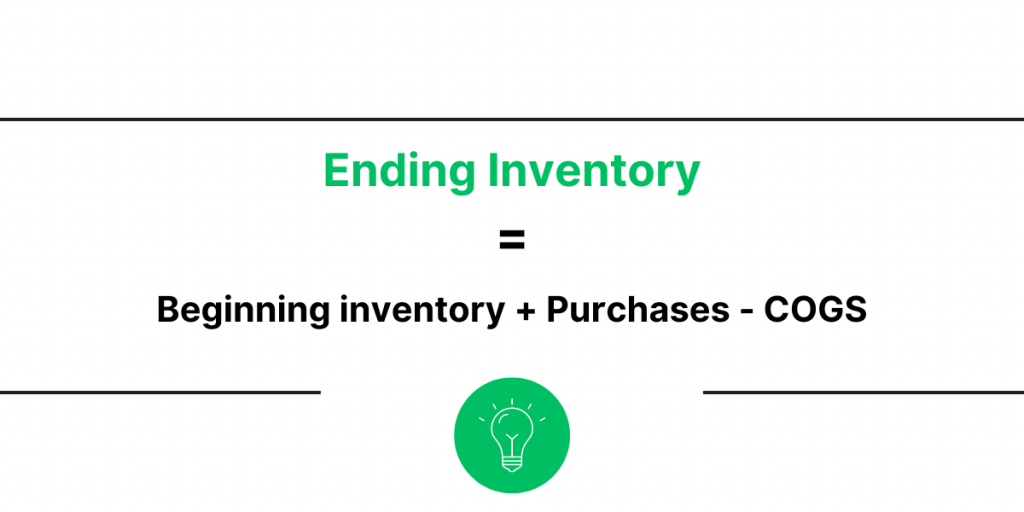

Ending inventory

In a perpetual inventory system, the ending inventory is continuously updated. It is the value of inventory left unsold at the end of the accounting period.

Formula:

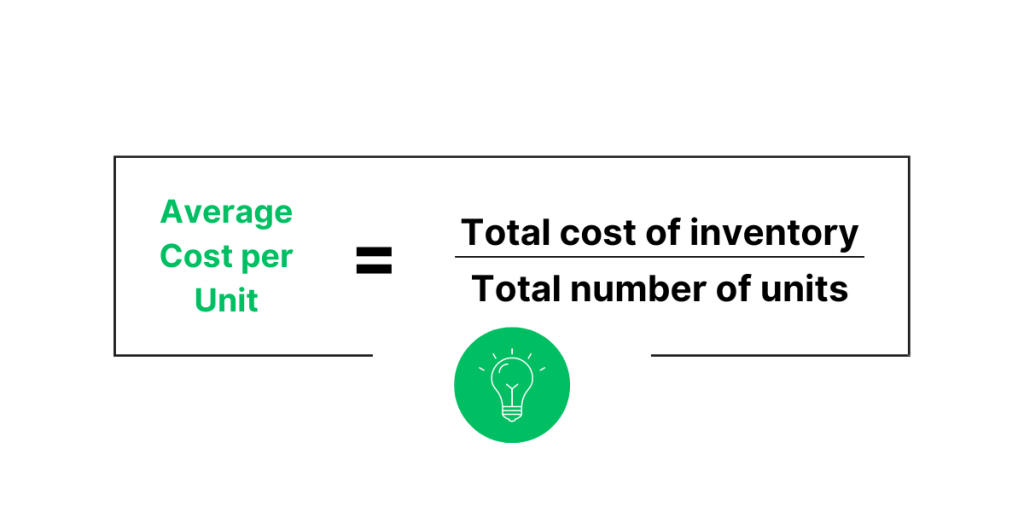

Average cost method

If a business uses the average cost method for inventory valuation, the cost of each item is determined by the average cost of all similar items in inventory.

Formula:

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) methods

These are methods to estimate the value of inventory and COGS. In FIFO, it is assumed that the oldest inventory items are sold first, while in LIFO, the most recently acquired items are sold first.

The formulas for FIFO and LIFO vary based on the specific inventory items sold and purchased.

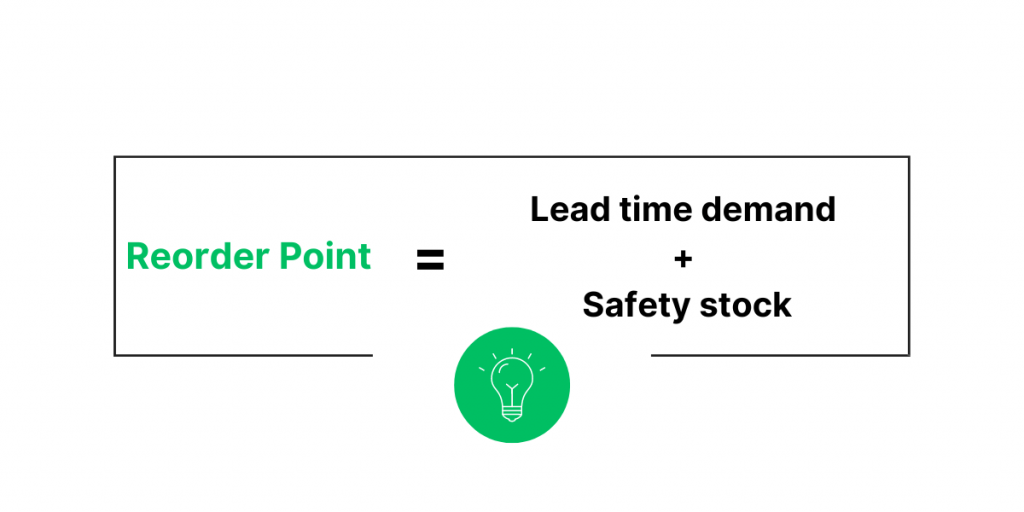

Reorder point formula

This formula determines when new inventory should be ordered, considering the lead time to replenish stock.

Formula:

Where Lead Time Demand = Average Daily Usage Rate x Lead Time in Days

These formulas are integral to the perpetual inventory system, enabling businesses to keep track of inventory costs, value, and efficiency and facilitating better financial and operational decision-making.

Note: The choice of specific formulas or methods, like FIFO or LIFO, depends on the business’s accounting policies and inventory management needs.

Conclusion

the perpetual inventory system represents a significant advancement in the field of inventory management, offering real-time accuracy, technological integration, and automated efficiency. While it requires an initial investment in technology and training, the long-term benefits in terms of accuracy, efficiency, and decision-making support are substantial.

Adopting a perpetual inventory system is a strategic decision that can lead to improved financial performance, better customer satisfaction, and a competitive edge in the marketplace. As technology continues to evolve, the perpetual inventory system will undoubtedly become even more sophisticated, further transforming the landscape of inventory management.

Learn more about accounting for medical practices.

.png)